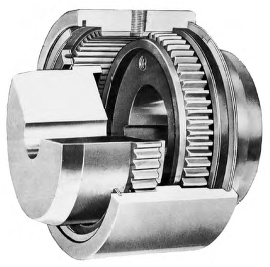

Why Coupling Grease?

Ample lubrication is vital for satisfactory gear coupling operation. Gear Coupling Grease is especially developed for gear coupling applications to improve coupling existence although significantly cutting down upkeep time. Its higher viscosity base oil and tackifier combine to keep the grease in area and reduce separation and it’s in comprehensive compliance with NSI/AGMA 9001-B97 lubrication recommendations.

Coupling Grease is dark brown in shade and manufactured using a lithium soap/polymer thickener, which has superior resistance to oil separation when subjected to large centrifugal forces generally identified in couplings. Bearing or common goal greases are inclined to separate and lose effectiveness resulting from substantial centrifugal forces on the various ingredients at large rotational speeds. These large centrifugal forces encountered in couplings separate the base oil through the thickeners. Heavy thickeners, which have no lubrication qualities, accumulate while in the gear tooth mesh region leading to premature coupling failure. Gear Coupling Grease is designed to remarkably resistant to centrifugal separation of your oil and thickener, which enables the lubricant to become utilized for any somewhat extended time period of time.

Among the list of tricks towards the good results of Gear Coupling Grease is the variable consistency through the entire operating cycle on the application. The consistency of our gear coupling grease alterations together with the working conditions. Functioning from the lubricant underneath real services conditions brings about the grease to develop into semi-fluid, functionally solash lubricating the dress  in surfaces of the coupling. Since the grease cools, it returns to your authentic consistency, thereby avoiding leakage.

in surfaces of the coupling. Since the grease cools, it returns to your authentic consistency, thereby avoiding leakage.

Gear Coupling Grease is available from stock in 14 oz. cartridges, 1 lb. and five lb. cans.

Functions

Minimizing of coupling dress in

Resistance to water washing

Corrosion and rust protection

Large load carrying capabilities

Extended relubrication frequency

Use at temperatures as much as 325° F

Staying in area beneath high speeds

Resistance to centrifugal separation

Reduction in down time & servicing cost

Gear Coupling Grease has a consistency which overlaps the NLGI grades 0 and 1. This grease is specially formulated that has a lithium/polymer thickener and fortified with corrosion, oxidation, extreme pressure, and a effective rust inhibitor additive package.